Tullamore

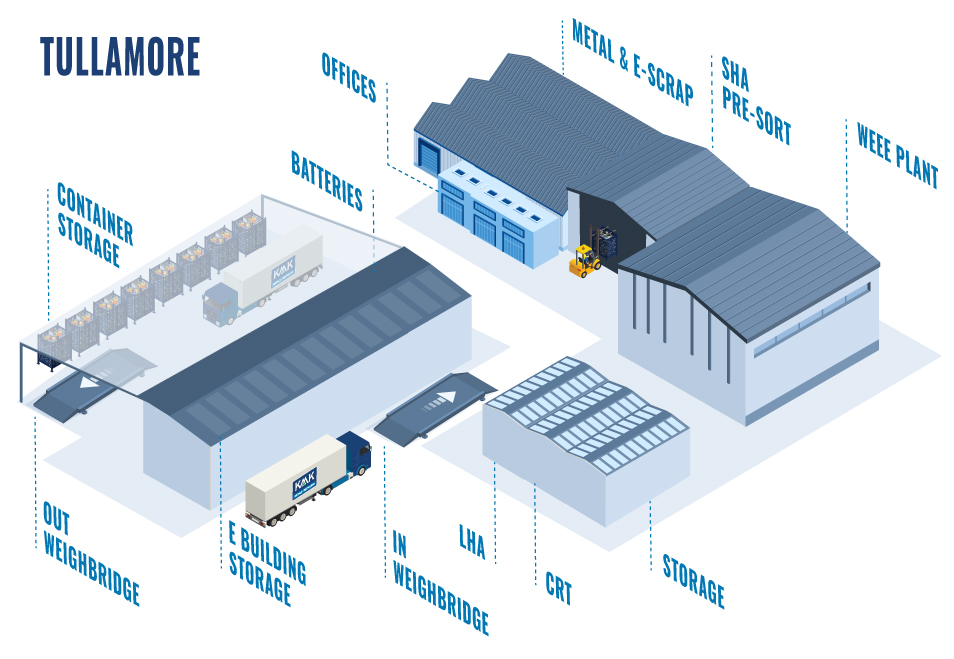

The KMK Metals Recycling facility in Tullamore is approximately 13,000 m2 in size (of which over 60% is covered area) and is authorised by the EPA under an Industrial Emissions Licence to process 35,000 tonnes of waste material per annum.

The main process on site, the WEEE Plant, was commissioned in 2011 and involves the processing of small household electronic appliances, treating up to 15,000 tonnes per annum. The process involves initial manual pre-sorting and the use of specialist equipment such as rotating and vibrating screens, shredders, magnets and wash plants to produces metals and metal-bearing commodities as well as plastics and components such as batteries and capacitors that are sent off-site for further processing and treatment.

Televisions and monitors are treated through our CRT process, which involves the hand disassembly of each screen into their individual metal, plastic and glass components as well as the capture of hazardous material generated through the process.

A hydraulic baler is used for the baling of steel fractions from our large household appliances process where items such as washing machines and dishwashers are de-polluted to remove hazardous components, thus ensuring compliance with the WEEE Directive.

The Tullamore site also operates a purpose-built battery sorting plant where highly-trained and skilled operatives identify and sort all types of batteries into their different chemistries. These batteries are brought to the facility from organised collections as well as being generated from other sorting processes on site.

In addition to the above processes, KMK operates an electrical scrap process where staff manually dismantle electrical scrap into their individual components such as aluminium, copper and steel, and a metals storage and handling area for processing, re-packaging and storage of metal wastes delivered direct to site. This area also functions as a transfer point for metal wastes generated from other processing activities on site.